Sustainable Supply of Scandium for the EU Industries from Liquid Residues from Chloride-Based TiO2 Plants

An EIT Raw materials co-founded project 2021-2024

Total budget: 4.5 million €

Today, no dedicated production plant exists worldwide, and no production and/or continuous supply in/for Europe is secured. Europe imports 100 % of scandium. The goal of the EU is to reach strategic independency with competitive prices.

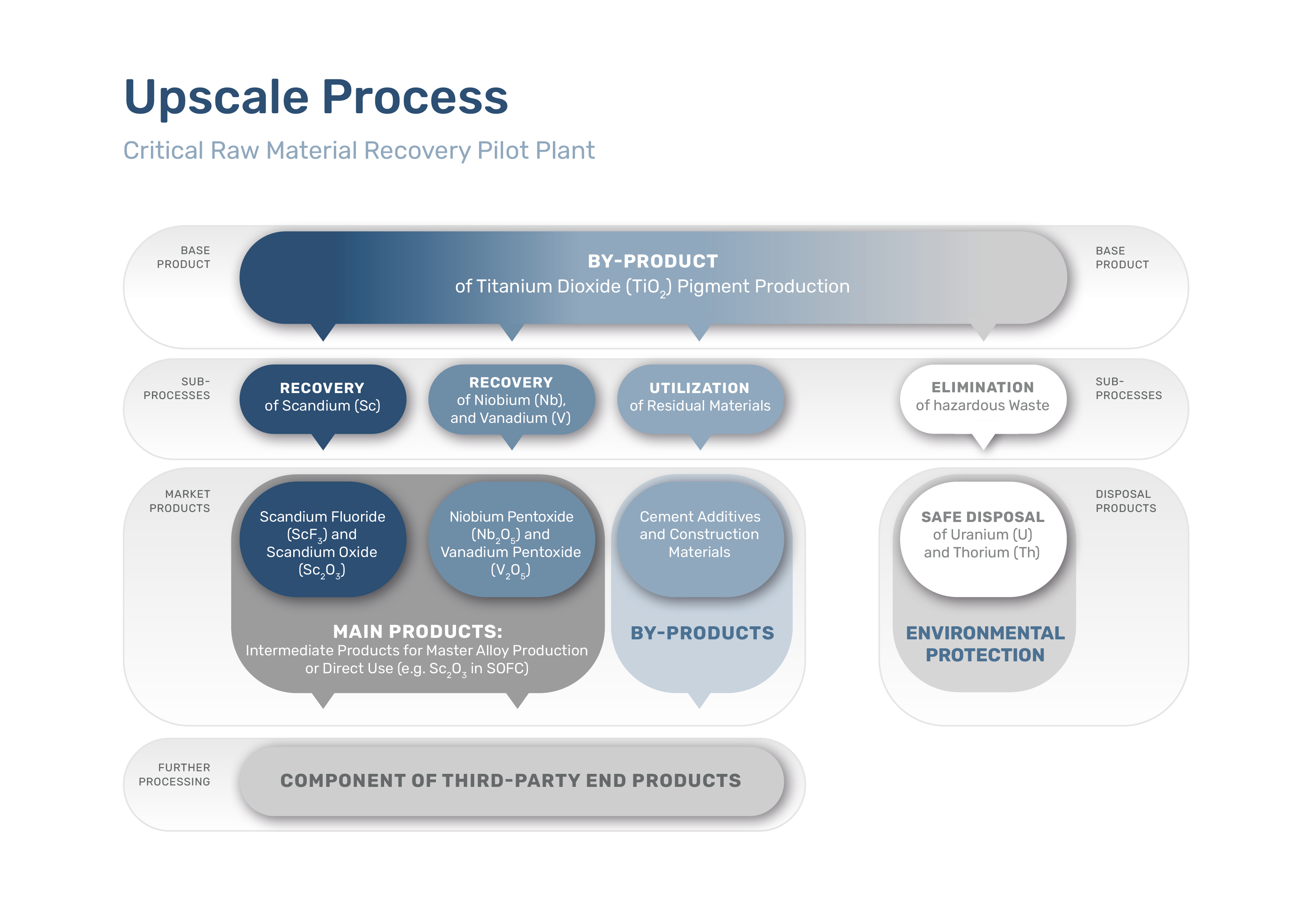

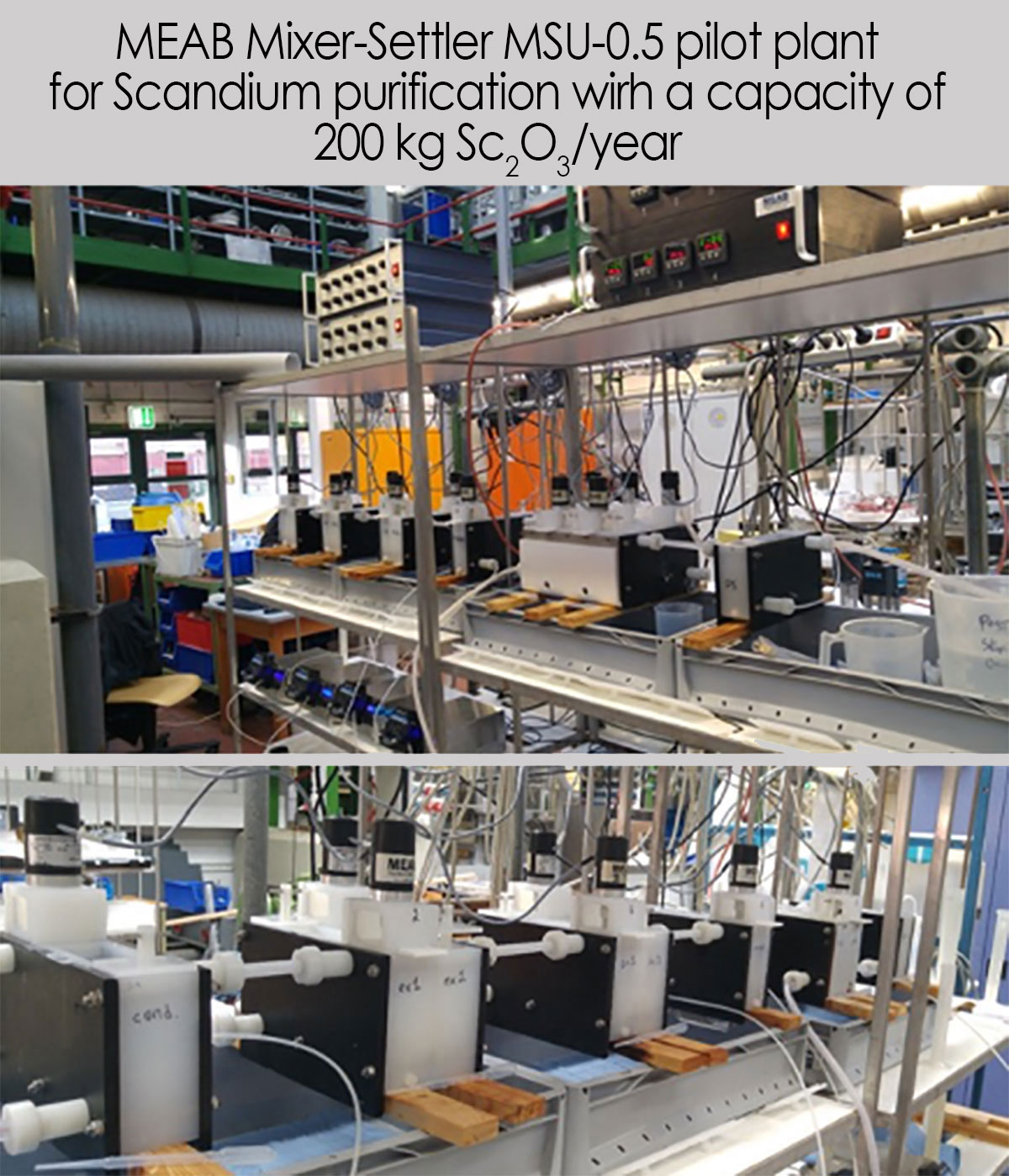

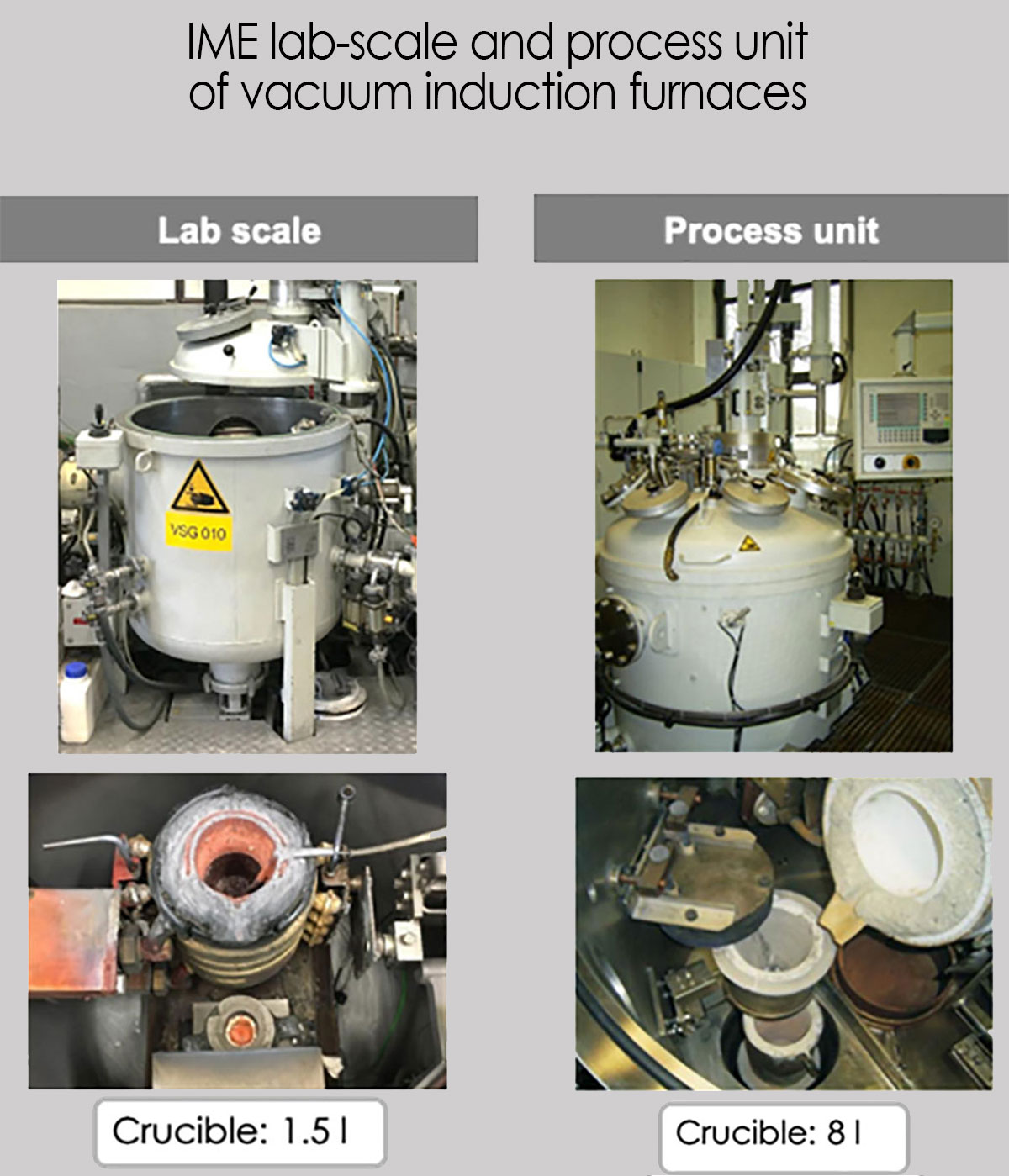

The ScaVanger company will be the first scandium producer from acid chlorine-rich solutions, by-products from TiO2 pigment production in the EU. The first plant will be operated at an EU TiO2 producer site. It can be adapted to other chlorine TiO2 production sites.

This plant can supply about 21t/a of Sc 2 O 3 , which represents about 2/3 of the expected EU consumption in 2028.

The Scavanger plant concept can be adapted to other chlorine TiO2 production sites in the EU and worldwide.

ScaVanger contributes to the EU’s circular economy and green deal action plans.

Application

Scandium is a scarce transition metal and a critical and strategic element for the EU. It is used essentially in Solid Oxide Fuel Cells (SOFC), Solid Oxigen Electrolysis Cells (SOEC), thin films for 5 G application, and aluminium-scandium alloys for the aeronautic and space industries.

Europe depends on 100 % of scandium imports mainly from China.

ScaVanger will ensure a stable, reliable and sustainable supply for scandium (Sc), but also vanadium (V) and niobium (Nb) for the European growing markets.

Sunfire´s high-temperature electrolysis module, the world´s largest

% of EU

tons per year

Mio €